Chapter 2: Introduction to Robotics and Automation: Basic Robot Components (Links, Joints, Actuators, Sensors)

CHAPTER 2: INTRODUCTION TO ROBOTICS AND AUTOMATION

- Links:These are the rigid structural components of a robot, like the arm segments in a robotic manipulator, which connect at joints and provide the physical framework for movement.

- Joints:Joints are the connection points between links, allowing relative motion between them, such as rotational joints (like a shoulder) or linear joints (like a sliding mechanism).

- Actuators:These are the "muscles" of a robot, converting electrical signals into physical motion to drive the joints and enable movement. Common actuator types include electric motors, pneumatic cylinders, and hydraulic actuators.

- Sensors:Sensors act as a robot's "eyes and ears", providing information about the environment like position, distance, force, vision, and temperature. This data is crucial for the robot to make informed decisions and adjust its actions accordingly.

- Links:These are the rigid structural components of a robot, like the arm segments in a robotic manipulator, which connect at joints and provide the physical framework for movement.

- Joints:Joints are the connection points between links, allowing relative motion between them, such as rotational joints (like a shoulder) or linear joints (like a sliding mechanism).

- Actuators:These are the "muscles" of a robot, converting electrical signals into physical motion to drive the joints and enable movement. Common actuator types include electric motors, pneumatic cylinders, and hydraulic actuators.

- Sensors:Sensors act as a robot's "eyes and ears", providing information about the environment like position, distance, force, vision, and temperature. This data is crucial for the robot to make informed decisions and adjust its actions accordingly.

- Control System:While not always considered a "basic component", a control system is essential to process sensory data, send commands to actuators, and coordinate the robot's movements.

- End Effector:This is the tool attached to the robot's manipulator, designed to perform specific tasks like gripping, welding, or painting.

- Imagine a robotic arm with multiple links connected by rotational joints. Electric motors (actuators) are used to rotate the joints, allowing the arm to move in different directions. Sensors like vision cameras and force sensors provide feedback about the environment, enabling the robot to precisely grasp an object.

2.1 Introduction

Robotics and automation have revolutionized various industries, from manufacturing and healthcare to logistics and aerospace. Robots are designed to perform repetitive, hazardous, and precise tasks with high efficiency. Understanding the basic components of a robot—such as links, joints, actuators, and sensors—is essential for designing and manufacturing reliable and high-performance robotic systems. This chapter provides an in-depth discussion on these fundamental components, their functions, design considerations, manufacturing techniques, and quality aspects, followed by cost analysis and a concluding summary.

2.2 Basic Robot Components

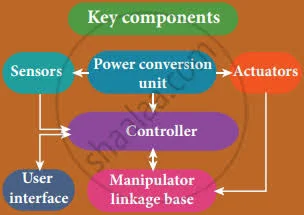

A robot consists of several key components that work together to achieve desired motion and functionality. The primary components include:

2.2.1 Links

Definition: Links are the rigid structures that connect different parts of a robot, forming its skeleton. These are analogous to human bones and provide support to the overall robotic structure.

Functions:

- Provide structural integrity.

- Facilitate motion between joints.

- Support payload and withstand mechanical stresses.

Design Considerations:

- Material selection (lightweight yet strong materials like aluminum, carbon fiber, and composites).

- Load-bearing capacity.

- Minimization of weight to reduce energy consumption.

Manufacturing Techniques:

- CNC machining.

- Casting and forging.

- 3D printing for complex geometries.

Quality Considerations:

- Precision in dimensions to ensure smooth motion.

- Material fatigue resistance.

- Corrosion and wear resistance.

2.2.2 Joints

Definition: Joints are the movable connections between links, enabling relative motion. They define the robot's degrees of freedom (DOF).

Types of Joints:

- Revolute Joint – Rotational movement around a fixed axis.

- Prismatic Joint – Linear movement along a single axis.

- Spherical Joint – Multi-axis rotational movement.

- Cylindrical Joint – Combination of rotational and linear motion.

Functions:

- Provide mobility to the robotic structure.

- Enable precise control of movement.

- Define the workspace and flexibility of the robot.

Design Considerations:

- Joint stiffness to avoid unwanted vibrations.

- Wear resistance for long-term reliability.

- Friction reduction for smooth motion.

Manufacturing Techniques:

- Precision machining.

- Advanced bearing systems for smooth operation.

- Additive manufacturing for customized designs.

Quality Considerations:

- High durability under continuous movement.

- Reduced backlash for accurate positioning.

- Efficient lubrication to minimize wear.

2.2.3 Actuators

Definition: Actuators are devices that convert energy (electric, hydraulic, or pneumatic) into mechanical motion. They are the driving force behind a robot’s movements.

Types of Actuators:

- Electric Actuators – Servo motors and stepper motors for precise control.

- Hydraulic Actuators – High power output for heavy-duty applications.

- Pneumatic Actuators – Fast and lightweight movement using compressed air.

Functions:

- Convert control signals into motion.

- Provide precise positioning and speed control.

- Enable force feedback and compliance control.

Design Considerations:

- Power-to-weight ratio for efficiency.

- Response time and accuracy.

- Heat dissipation and cooling mechanisms.

Manufacturing Techniques:

- Advanced winding techniques for motors.

- 3D printing for custom actuator housings.

- High-precision assembly for minimal losses.

Quality Considerations:

- Reliability in different environmental conditions.

- Longevity and maintenance ease.

- Low power consumption for efficiency.

2.2.4 Sensors

Definition: Sensors provide feedback to the robot, enabling it to perceive and interact with its environment.

Types of Sensors:

- Position Sensors – Encoders, potentiometers.

- Force/Torque Sensors – Measure interaction forces.

- Vision Sensors – Cameras and LiDAR for object detection.

- Proximity Sensors – Detect obstacles and avoid collisions.

- Temperature Sensors – Monitor heat buildup in actuators.

Functions:

- Enhance robot intelligence through environmental perception.

- Improve accuracy and safety.

- Enable adaptive responses to dynamic conditions.

Design Considerations:

- Sensitivity and range.

- Integration with control systems.

- Signal processing and noise reduction.

Manufacturing Techniques:

- MEMS technology for miniaturized sensors.

- Optical and laser-based fabrication for high precision.

- AI-based calibration for enhanced accuracy.

Quality Considerations:

- High resolution for precise feedback.

- Durability in harsh conditions.

- Minimal lag for real-time processing.

2.3 Cost Considerations

The cost of developing and deploying robotic systems depends on multiple factors:

- Material Costs – High-performance materials like titanium and composites increase costs.

- Manufacturing Costs – Precision machining and advanced techniques like 3D printing influence pricing.

- Labor and Assembly Costs – Skilled labor for assembly and calibration.

- Maintenance Costs – Durability and replacement part availability.

- Software and AI Integration – Adding intelligence to robots incurs additional expenses.

Reducing costs while maintaining performance requires optimization in design, efficient manufacturing techniques, and modular assembly approaches.

2.4 Conclusion

Robotics and automation are transforming industries by improving productivity, accuracy, and safety. Understanding the fundamental components—links, joints, actuators, and sensors—is crucial for designing high-quality robots. Design considerations, manufacturing techniques, and quality control play essential roles in ensuring reliability and efficiency. While costs can be significant, strategic design choices and technological advancements help balance affordability and performance. As robotics continues to evolve, innovations in materials, AI, and automation will further enhance their capabilities and applications.

Comments

Post a Comment

"Thank you for seeking advice on your career journey! Our team is dedicated to providing personalized guidance on education and success. Please share your specific questions or concerns, and we'll assist you in navigating the path to a fulfilling and successful career."