Chapter 18: Robot Programming – Motion Programming (Point-to-Point, Continuous Path)

Abstract

In robot programming, motion programming involves defining how a robot moves, with two primary approaches: point-to-point (PTP) and continuous path (CP). PTP focuses on moving between specific points, while CP allows for precise path following, including curves.

- Definition:PTP motion involves moving a robot from one specific point to another, often in a straight line, where the path taken is not as critical as the end position.

- Applications:Suitable for tasks like pick-and-place operations, where the robot needs to move to a specific location to grasp or release an object.

- Programming:The robot is programmed with the coordinates of the starting and ending points, and it moves directly between them.

- Example:A robot moving from one assembly station to another to pick up a part and place it in a different station.

- Definition:CP motion allows the robot to follow a pre-defined path, which can include straight lines, curves, and arcs.

- Applications:Ideal for tasks that require precise path following, such as arc welding, painting, or gluing.

- Programming:The robot is programmed with a series of points that define the desired path, and it moves along these points to follow the path.

- Example:A robot following a curved path to apply a sealant to a part.

- Teach-in Method:Programmers can manually move the robot arm through the desired path, and the controller unit stores a large number of individual point locations along the path in memory.

Feature | Point-to-Point (PTP) | Continuous Path (CP) |

|---|---|---|

Path Control | Path is not critical, only end position matters | Path is critical, and the robot must follow it precisely |

Applications | Pick-and-place, assembly | Welding, painting, gluing |

Programming | Define start and end points | Define a series of points along the path |

18.1 Introduction

Point-to-point motion involves moving a robot between predefined positions without considering the path between them, whereas continuous path motion enables smooth and precise movement along a defined trajectory. These motion techniques are widely used in industrial automation, robotic surgery, welding, painting, and pick-and-place applications.

This chapter explores the concepts, implementation, advantages, and challenges of these motion programming techniques, along with real-world applications.

18.2 Fundamentals of Robot Motion Programming

18.2.1 What is Motion Programming?

Motion programming refers to the process of defining and controlling the movement of a robot's joints or end effector to perform specific tasks. It involves:

- Path Planning: Determining the trajectory the robot will follow.

- Motion Control: Managing speed, acceleration, and stopping points.

- Interpolation Methods: Calculating intermediate positions for smooth movement.

18.2.2 Types of Robot Motion Programming

There are two primary types of motion programming:

- Point-to-Point (PTP) Motion

- Continuous Path (CP) Motion

Each method is suited for specific applications based on precision, speed, and control requirements.

18.3 Point-to-Point (PTP) Motion

18.3.1 Definition

Point-to-point (PTP) motion involves moving a robot from one predefined position to another without concern for the path taken between them. The system calculates an optimal trajectory for each movement, but the robot does not follow a strict path between points.

18.3.2 How PTP Motion Works

- The user defines key positions (waypoints) in space.

- The robot moves rapidly between these points, using an optimized trajectory.

- The motion controller ensures each joint moves efficiently to the target position.

18.3.3 Applications of PTP Motion

- Pick-and-Place Operations: Moving objects between predefined locations.

- Assembly Line Robots: Positioning parts in manufacturing.

- CNC Machines: Moving between tool change locations.

- Medical Robotics: Precise positioning of robotic surgical tools.

18.3.4 Advantages and Disadvantages of PTP Motion

| Advantages | Disadvantages |

|---|---|

| Faster execution time | No control over intermediate path |

| Suitable for high-speed automation | Not ideal for tasks requiring smooth motion |

| Lower computational complexity | May result in jerky movements |

| Reduces wear on mechanical components | Limited in applications requiring precision path following |

18.4 Continuous Path (CP) Motion

18.4.1 Definition

Continuous path (CP) motion involves smooth and controlled movement along a predefined trajectory, allowing for precise control of position, velocity, and acceleration at every point along the path.

18.4.2 How CP Motion Works

- The robot follows a continuous trajectory, rather than discrete points.

- Intermediate positions are interpolated to create a smooth motion.

- The motion controller regulates speed and acceleration to ensure seamless movement.

18.4.3 Applications of CP Motion

- Welding Robots: Ensuring a smooth and even weld.

- Painting and Coating: Maintaining a uniform application of paint.

- Robotic Surgery: Precise movement in delicate procedures.

- 3D Printing and Additive Manufacturing: Controlled material deposition.

18.4.4 Advantages and Disadvantages of CP Motion

| Advantages | Disadvantages |

|---|---|

| Smooth and precise motion | More computationally demanding |

| Essential for continuous operations | Requires higher programming effort |

| Allows fine control over speed and acceleration | Higher hardware wear due to continuous movement |

| Reduces mechanical stress and vibration | May require additional sensors for accuracy |

18.5 Comparison of PTP and CP Motion

| Feature | Point-to-Point (PTP) | Continuous Path (CP) |

|---|---|---|

| Movement Control | Moves only between specific points | Follows a defined trajectory |

| Path Consideration | Ignores intermediate path | Precisely controls motion along the path |

| Speed | Faster | Slower but smoother |

| Precision | Less precise | High precision |

| Computational Complexity | Low | High |

| Applications | Pick-and-place, assembly | Welding, painting, surgery |

18.6 Motion Interpolation Methods

Interpolation determines how a robot moves between two points. Common methods include:

18.6.1 Linear Interpolation

- Moves the end effector in a straight line between two points.

- Used in applications requiring direct movement, such as CNC machining.

18.6.2 Circular Interpolation

- Moves the end effector along an arc between two points.

- Used in robotic painting, cutting, and welding.

18.6.3 Spline Interpolation

- Uses polynomial curves to generate smooth trajectories.

- Used in high-precision applications like robotic surgery.

18.7 Programming PTP and CP Motion in Robot Languages

18.7.1 PTP Motion Example in RAPID (ABB Robots)

MoveJ p1, v100, z50, tool1; // Move to point 1

MoveJ p2, v100, z50, tool1; // Move to point 2

MoveJ p3, v100, z50, tool1; // Move to point 3

18.7.2 CP Motion Example in KUKA KRL (KUKA Robots)

LIN p1 C_DIS; // Move in a straight line to p1

LIN p2 C_DIS; // Move in a straight line to p2

CIRC p3, p4 C_DIS; // Move in a circular path from p3 to p4

18.8 Challenges in Motion Programming

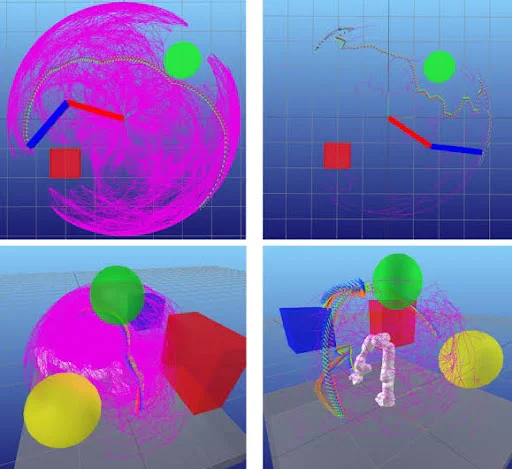

- Collision Avoidance: Ensuring robots do not collide with objects.

- Environmental Factors: Variations in lighting, temperature, and workspace can affect movement.

- Hardware Limitations: Motors and sensors may have precision limitations.

- Computational Overhead: Continuous path motion requires real-time processing.

18.9 Future Trends in Robot Motion Programming

- AI-Driven Motion Planning: Using deep learning for adaptive motion control.

- Digital Twin Technology: Simulating robot motion before deployment.

- Advanced Sensors for Precision Control: LIDAR, cameras, and IMUs enhancing path accuracy.

- Collaborative Robotics: Human-robot interaction requiring smooth, adaptive motion.

18.10 Summary

Motion programming defines how robots move in space. Point-to-point (PTP) motion is ideal for tasks requiring quick transitions between predefined points, whereas continuous path (CP) motion is used for smooth and precise movement. The choice between PTP and CP depends on the application, with PTP being suitable for pick-and-place tasks and CP being essential for welding, painting, and surgical applications.

Advancements in AI, sensor technology, and digital simulations are shaping the future of robotic motion programming, enabling robots to achieve greater precision, adaptability, and efficiency.

Comments

Post a Comment

"Thank you for seeking advice on your career journey! Our team is dedicated to providing personalized guidance on education and success. Please share your specific questions or concerns, and we'll assist you in navigating the path to a fulfilling and successful career."