What's Exactly Aggregate Production Planning ? Discover It's significance, Costs, Steps , Strategies + Much More...!!

The concept of aggregate production planning denotes the process of determining the overall quantities of products to be manufactured or produced in a plant or other manufacturing facility during a medium-term planning period such as a month, or a quarter. The aggregate plan output comprises of the total quantities of each product or a group of products to be manufactured in the plan period of going into details of the scheduling of different manufacturing activities required to attain the planned production levels. The aggregate production will also not specify details such as the dates when material ordered against individual customer orders will be ready for delivery. The aggregate production plan is designed to establish overall production targets and as input for planning availability of other inputs and supporting activities to meet the production targets.

- Routing.

- Loading.

- Scheduling.

- Dispatching.

- Follow up.

- Inspection.

- Corrective.

- Sales forecasts.

- Inventory investment.

- Capital equipment utilization.

- Work force capacity.

- Skills training requirements.

- Corporate policies concerning customer service levels, overtime, and subcontracting.

Graphical Methods

Graphical techniques are popular because they are easy to understand and use. These plans work with a few variables at a time to allow planners to compare projected demand with existing capacity. They are trial-and-error approaches that do not guarantee an optimal production plan, but they require only limited computations and can be performed by clerical staff.

Creating an effective aggregate plan involves several key steps:

- Data Collection:

- Gather accurate and up-to-date data on historical demand patterns, production capacities, and workforce capabilities.

- Collaborative Input:

- Involve key stakeholders from different departments such as production, finance, and sales to ensure a comprehensive perspective.

- Risk Analysis:

- Identify potential risks and uncertainties that may impact the plan, such as market volatility, supply chain disruptions, or unexpected events.

- Technology Integration:

- Leverage technology tools and software for data analysis, forecasting, and simulation to enhance the accuracy and efficiency of the planning process.

- Alternative Scenarios:

- Develop contingency plans and explore alternative scenarios to address unexpected changes in demand, supply, or other external factors.

- Continuous Improvement:

- Establish a feedback loop for continuous improvement, allowing the plan to evolve based on real-time data and performance feedback.

- Employee Training:

- Provide training for employees to adapt to changes in production schedules, ensuring a skilled and flexible workforce.

- Environmental Considerations:

- Account for environmental factors, such as sustainability goals or regulations, in the planning process.

- Supplier Collaboration:

- Collaborate with suppliers to synchronize their production and delivery schedules with your aggregate plan, ensuring a smooth supply chain.

- Customer Feedback Integration:

- Incorporate customer feedback into the planning process to align production with market preferences and enhance customer satisfaction.

By incorporating these specific aspects into the creation of an aggregate plan, businesses can enhance the effectiveness and adaptability of their planning strategies.

Several factors influence aggregate planning, impacting how businesses align production with demand:

1. Demand Variability:

Fluctuations in customer demand can significantly affect the production planning process.

2. Production Flexibility:

The adaptability of production processes to changes in volume or product mix plays a vital role.

3. Lead Time:

The time required to make adjustments in production levels or receive new inventory influences planning.

4. Capacity Constraints:

Limitations on resources, such as machinery, labour, or facilities, impact overall production capabilities.

5. Inventory Levels:

The amount of stock on hand affects the need for production adjustments.

6. Workforce Considerations:

The availability, skills, and costs associated with the workforce influence production planning.

7. Supply Chain Disruptions:

External factors like raw material shortages or transportation issues can disrupt planning.

8. Government Regulations:

Compliance with regulations may impact production and inventory decisions.

9. Cost Factors:

Production, labor, and inventory costs play a significant role in planning considerations.

10. Market Conditions:

Changes in the market, including competition and pricing, can impact planning strategies.

Taking these factors into account enables businesses to develop effective aggregate planning strategies that adapt to their operational and market realities.

For success of the Aggregate Production Planning the following inputs are required;

- An aggregate demand forecast for the relevant period

- Evaluation of all the available means to manage capacity planning like subcontracting, outsourcing, etc.

- Existing operational status of the workforce (number, skill set, etc.), inventory level and production efficiency

Aggregate planning will ensure that the organization can plan for workforce level, inventory level and production rate in line with its strategic goal and objective.

In the rapidly advancing landscape of manufacturing, the integration of Artificial Intelligence (AI) has ushered in a new era of innovation and optimization in production scheduling. AI-powered tools have emerged as transformative assets, empowering manufacturers to unlock unprecedented levels of efficiency, agility, and precision in their production processes.

By harnessing the capabilities of AI algorithms, data-driven insights, and real-time adaptability, these tools have revolutionized the way production schedules are planned, executed, and optimized. In this section, we delve into the diverse array of AI-powered tools that are reshaping production scheduling, exploring their applications, benefits, and the immense potential they hold for driving the manufacturing industry towards a more intelligent and productive future.

A. Advanced Planning and Scheduling (APS) systems

Advanced Planning and Scheduling (APS) systems are at the forefront of AI-powered tools revolutionizing production scheduling in the manufacturing industry. These sophisticated software solutions leverage the capabilities of AI algorithms and data analytics to optimize production schedules, resource allocation, and supply chain management.

APS systems enable manufacturers to address the complexities and uncertainties of modern manufacturing environments, leading to more efficient and effective production processes.

B. Robotics and automation in scheduling

In the realm of production scheduling, robotics and automation have emerged as transformative technologies that work in tandem with AI-driven solutions to optimize manufacturing processes. The integration of robotics and automation in scheduling brings increased efficiency, flexibility, and precision to production operations.

C. Internet of Things (IoT) integration for data-driven insights

The Internet of Things (IoT) is revolutionizing production scheduling in manufacturing by enabling the seamless integration of physical devices, sensors, and machines with digital technologies. Through IoT integration, manufacturers gain access to a wealth of real-time data and actionable insights, enhancing the data-driven decision-making process in production scheduling.

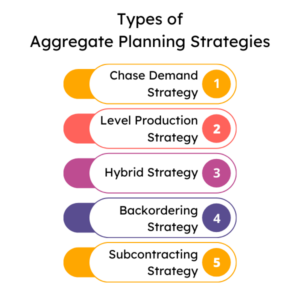

Businesses commonly utilize various aggregate planning strategies to align production with demand. Below listed are the types of aggregate planning strategies:

1. Chase Demand Strategy:

- Adjust production levels to match changes in demand.

- Suitable for industries with flexible production capabilities.

2. Level Production Strategy:

- Maintain a steady production rate and use inventory to absorb demand fluctuations.

- Suitable for industries with high setup costs or limited flexibility.

3. Hybrid Strategy:

- A combination of chase demand and level production strategies.

- Offers a balance between adjusting production and maintaining a stable rate.

4. Backordering Strategy:

- Allow demand to exceed supply temporarily, fulfilling backlogged orders later.

- Applicable when back-ordering is acceptable to customers.

5. Subcontracting Strategy:

- Outsource production to third-party suppliers during periods of high demand.

- Useful for maintaining flexibility without expanding internal resources.

Selecting the appropriate strategy of aggregate planning depends on factors such as industry characteristics, production capabilities, and customer expectations. Businesses often employ a mix of these strategies to effectively manage their aggregate planning processes.

The prime objective of Aggregate Production Planning is to judge company policies and management inputs linked to operations, distribution and marketing, materials, accounting and finance, engineering and human resources to reduce the price and increase revenue, enhance customer service, lessen inventory investment, decrease changes in production rates, reduce changes in work-force levels, boost utilization of plant and equipment

Q. What's the Techniques of Aggregate Planning?

Ans :

Various techniques are used to perform the task of aggregate planning. Usually, there are two categories: Informal trial-and-error techniques and mathematical techniques. In practice, informal techniques are more commonly used. However, a substantial amount of research has been done to mathematical techniques, but still, they are not as extensively used, they often serve as a basis for comparing the effectiveness of alternative techniques for aggregate planning.

There are several steps in the general procedure for aggregate planning:

- Determine the demand for each period.

- Determine capacities (regular time, overtime, subcontracting) for each period.

- Identify a company or departmental policies that are pertinent (e.g., maintain a safety stock of 5 percent of demand, maintain a reasonably stable workforce).

- Determine unit costs for regular time, overtime, subcontracting, holding inventories, backorders, layoffs, and other relevant costs.

- Develop alternative plans and compute the cost for each activity.

- If satisfactory plans emerge, select the one that best satisfies objectives.

- Repeat the steps, if satisfactory results not obtained

References

Designing production planning and control in smart manufacturing 2024, Computers in Industry

A review on aggregate production planning under uncertainty: Insights from a fuzzy programming perspective 2024, Engineering Applications of Artificial Intelligence

Designing a reliable aggregate production planning problem during the disaster period 2023, Sustainable Operations and Computers

Multi-facility aggregate production planning with prosumer microgrid: A two-stage stochastic program 2022, Journal of Cleaner Production

Models and algorithms for production planning, scheduling and sequencing problems: A holistic framework and a systematic review 2022, Journal of Industrial Information Integration

Aggregate Production Planning and Scheduling in the Industry 4.0 Environment 2022, Procedia Computer Science

Yu VF, Kao H-C, Chiang F-Y, Lin S-W. Solving Aggregate Production Planning Problems: An Extended TOPSIS Approach. Applied Sciences. 2022; 12(14):6945. https://doi.org/10.3390/app12146945

Comments

Post a Comment

"Thank you for seeking advice on your career journey! Our team is dedicated to providing personalized guidance on education and success. Please share your specific questions or concerns, and we'll assist you in navigating the path to a fulfilling and successful career."