What's the Differences between Surface Roughness and Surface Finish !!

Abstract

Surface roughness refers to the quantifiable measurement of the irregularities on a surface, while surface finish is a qualitative assessment based on its appearance or indirectly from the roughness value. However, in machine shops, it is common for the term surface finish to be used to describe only the surface roughness.

Keywords:

Surface Roughness, Surface finish , Parameters of Surface Finish

Learning Outcomes

After undergoing this article you will be able to understand the differences between Surface Roughness and Surface Finish

1. Surface Roughness: Basic concepts

Surface Roughness is the measure of macro and micro asperities and irregularities present on a finished surface after machining. It is the quantitative approach to find out height of peaks and depth of valleys of surface asperities. There are various instruments to facilitate such measurement.

2. Surface finish : Basic concepts

A qualitative approach that describes the appearance of a surface, such as a stainless steel plate or sheet. It can be described using terms like "bad", "poor", "good", "glossy", or "fine". Surface finish can be subjective and affected by human bias because it doesn't have a numerical value. It can be obtained through manufacturing processes like machining, grinding, honing, or lapping. Surface finish is important for mechanical components that need to fit together, move against each other, or create a seal.

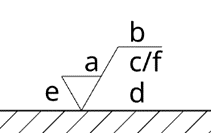

a - average roughness value (Ra)

b - production method, coating, note, or other additional information

c - roughness sampling length in millimeters or inches

d - direction of the surface lay

e - minimum material removal requirement in millimeters

f - alternate surface finish parameter

4. Differences between surface roughness and surface finish

The Various differences between surface roughness and surface finish are given below in the table format below

| Surface Roughness | Surface Finish |

|---|---|

| It is one quantifiable physical parameter and can be expressed using numerical value with unit. | It is not quantifiable parameter, instead a qualitative one. It can be expressed using attributes only. |

| It always has an absolute value. It is independent of application and also free from human bias. | It does not have absolute value. Mostly it relies on application and also affected by human bias. |

| Roughness can be measured directly using suitable instrument. | Finish cannot be measured. |

| Roughness of machined surface can also be estimated from relevant process parameters and tool features. | Surface finish cannot be estimated using mathematical formula. Value of roughness is used to indirectly specify finish. |

5. Conclusions

The desired surface quality is a crucial aspect of machined parts. Surface finish is the specific procedure implemented to achieve the desired level of surface roughness on a fabricated part. It is a critical factor that influences the functionality, appearance, and longevity of the final product, being influenced by the manufacturing processes employed.

Comments

Post a Comment

"Thank you for seeking advice on your career journey! Our team is dedicated to providing personalized guidance on education and success. Please share your specific questions or concerns, and we'll assist you in navigating the path to a fulfilling and successful career."