What is Drilling Machine, Where it is Used and How? Know It's Types and Specifications!

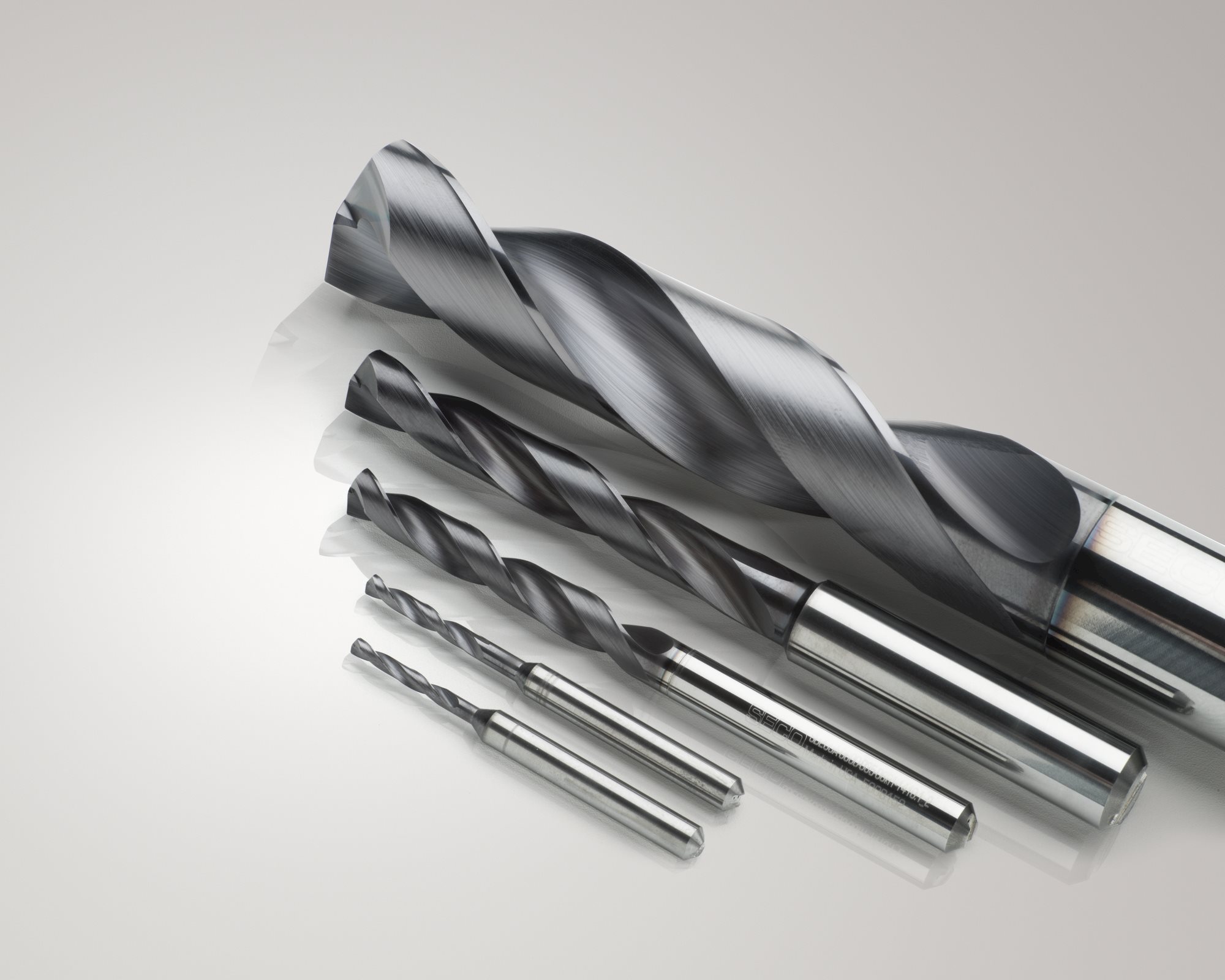

Drilling uses a drill bit that rotates rapidly as it moves through the workpiece, effectively shaving away the solid material and creating a round hole. Drill bits are available in a comprehensive range of sizes to facilitate different hole sizes. Manufacturers of cutting tool equipment are constantly in a state of research and development to provide their customers the most cost-effective solution. Working with technically smart tool salespeople is important so that you are always at the cutting edge of what is available.

Drill bits are multi-point tools, which means they provide a minimum of two cutting edges. As such, the drilling process is fairly efficient and is particularly beneficial for increasing the axial length of a hole. The depth and diameter of the hole is directly dependent on the size of the drill bit.

It is important to note that improper chip evacuation can be a problem in this process, particularly on vertical style machines when drilling deeper holes. High pressure coolant will in most instances take care of this issue. Machinists must use the correct machining strategy to evacuate chips properly rather than continuing to drill without pause.

The drilling process is versatile and can be used to create holes of a variety of diameters and depths. Depending on the available equipment, machinists can drill using:

Horizontal milling machines

Vertical milling machines

Machining centers

Drill presses

Hand tools

Types

of Drilling Machine:-

made in many different types and sizes, each designed to handle a class of work or specific jobs to the best advantages.

types of drilling

machines are:

Portable drilling machine 5. Gang drilling machine

Sensitive drilling

machine 6. Multiple spindle drilling machine

Bench mounting 7. Automatic

drilling machine

Floor mounting 8. Deep hole

drilling machine

Upright drilling

machine A. Vertical

Round column

section B. Horizontal

Box column section

Radial drilling machine

Plain

Semi universal

Universal

Portable

drilling machine:-

As the name implies

this type of drilling machine can be operated with ease anywhere in the workshop

and is used for drilling

holes in workshop

in any position which cannot be drilled in a standard

drilling machine.

Some of portable machine

are operated by hand power

but some of the machine

are driven by individual motor.

The maximum

size of hole it can accommodate is not more than 12 to 18 mm.

Sensitive

drilling machine:-

Sensitive drilling

machine is a small machine

designed for drilling

small holes at a

high speed in light jobs.

The base of machine

may be mounted on a bench or on a floor.

drill spindle, 3 – Sleeve,

4 – Cone pulley, 5 – V Belt, 6 – Head,

7– Driving motor, 8 – Vertical

column, 9 – Base

It consists

of a vertical column, horizontal table, a head

supporting motor and driving

mechanism for driving and rotating

the drill.

There is no automatic

feed of drill spindle.

Drill is fed to the work by purely

hand control.

Hand feed permits the operator

to feel or sense the progress of the drill into work, so that if the drill becomes worn

out or jams on any account, the pressure on

the drill may be released immediately to prevent it from breaking.

Sensitive drilling

machine are capable

of rotating drills

of diameter from 1.5 to 15.5mm

Upright drilling machine:-

The upright

drilling machine is designed for handling medium

sized workpiece.

Its construction is

very similar to a sensitive drilling machine for having a vertical column mounted

upon the base.

But this is larger and

heavier than sensitive drilling machine and is supplied with power feed arrangement.

·

In an upright drilling

machine a large number of spindle speeds

and feeds may be

available for drilling different types of work.

There are two types of upright

drilling machines.

Round column

section or pillar drilling machine

Box column section

|

| Upright drilling machine |

drive to spindle, 2 – Spindle, 3 – Over head shaft,

4 – Back stay, 5 – Cointer shaft

cone pulley, 6 – Fast

and loose pulley,

7 – Table elevating

handle, 8 – Foot padel,

9 – Base, 10 – Rack on column, 11 – Table

elevating

– Table, 14 – Column,

– Hand wheel forquick hand feed,

16 – Hand wheel for sensitive hand

feed

Round column section or

pillar drilling machine consists of a round column that rises from

the base which

rests on the floor, an arm and a round

table assembly and a drill head assembly.

three adjustments for locating workpiece under spindle.

Arm and table may be moved up and down on the column.

Arm and table may be moved in arc up to 180o around the column.

The table

may be rotated 360o about its own center.

not very rigid so useful for lighter

work.

size of holes that the machine can drill is not more than 50 mm.

Upright drilling

machine with box column section

has the square

table fitted on the

slides at the front face of the machine column.

Heavy box column gives the machine

strength and rigidity.

The table

is raised or lowered by an elevating screw that gives

additional support to the

table.

This special

feature permits machine

to work with

heavier workpiece and

holes more than 50 mm diameter

can be drilled by it.

Radial

drilling machine:-

The radial drilling

machine is intended for drilling medium to large and heavy workpieces.

The machine

consists of a heavy, round,

vertical column mounted

on large base.

The column supports a

radial arm which can be raised and lowered and may be swing around to any position over the work bed.

The drill

head containing mechanism for rotating and feeding the drill is mounted on a radial arm and can be moved horizontally on the guide ways.

|

| Radial drilling machine |

2 – Column, 3 – Radial arm,

4 – Motor for elevating the arm, 5 – Elevating screw,

6 – Guide ways,7 – Motor for driving the drill spindle, 8 – Drill head,

9 – Drill spindle, 10 – Table

These movements

are useful to locate drill at any desired position.

When several

holes are drilled

on a large workpiece the

position of arm and the drill

may be moved from one position to other after drilling first

hole without altering

the setting of the workpiece.

In a Plain radial

drilling machine, provisions are made for vertical adjustment of the arm,

horizontal movement of the drill head along with the arm and circular movement of the arm in horizontal plane about the vertical column.

In a Semi universal drilling machine, in addition to the above three movement,

the drill head can be swung about

a horizontal axis

perpendicular to the arm. This

fourth movement of the drill head permits drilling

hole at an angle to the horizontal plane other than the normal

position.

In a Universal drilling

machine, in addition

to the above four movements, the arm holding the drill head may be rotated on a horizontal axis. All these

five movements in a universal drilling

machine enable it to drill on a workpiece at any angle.

Gang

drilling machine:-

When a number of single spindle

drilling machine columns

are placed side by side

on a common worktable, machine is known

as the gang drilling

machine.

The speed and feed of the spindle may be controlled individually.

This type of machine

is specially adapted

for production work.

A series of operations

may be performed on the work by simply shifting the work from on to other

position on the work table.

Multiple spindle drilling

machine:-

The function

of a multiple spindle drilling

machine is to drill a number of holes in a

piece of work simultaneously and

to produce the same pattern

of holes in a number of identical pieces in a mass production work.

The spindles

are so constructed that their center distance

may be adjusted in any position as per requirement of various jobs.

Automatic drilling machine:-

Automatic machine

can perform a series of machining operations at successive units and transfer the work from one unit to the other automatically.

Once the work is loaded at first machine

then this will move from one machine

to the other where

different operations may be performed and finished product

comes out at last without any manual handling.

Deep

hole drilling machine:-

Special machined

and drills are required for drilling deep holes in rifle barrels,

crank shaft, long shafts etc.

The machine

is operated at high speed

and low feed.

For that work is usually rotated

while drill is fed into work and sometimes both work

and drill are rotated.

The machine

may be horizontal and vertical

type.

Size of Drilling Machine

The size of a drilling machine

varies with the type of machine being

considered.

A portable

drilling machine is specified by maximum diameter

of the drill that it can

hold.

The sensitive and

upright drilling machines are specified by the diameter of the largest piece that can be centered

under the spindle.

To specify

a drilling machine

fully further particulars such as the maximum size of

drill that the machine can operate, table diameter, the maximum spindle travel,

numbers of spindle speed and feeds available, Morse taper number of the drill spindle, power input, floor space

required, net weight of the machine, etc. are all needed.

The size

of the radial

drilling machine is specified by the diameter of the column

and length of the arm. Other particulars such as maximum drilling

radius, minimum drilling radius, spindle

speeds and feeds, etc. should

also be stated

to specify the machine fully.

Work Holding Devices:-

machine it is absolutely necessary to secure the work firmly

on the drilling machine table.

commonly used for holding the work in a drilling

machine are:

methods of holding the work directly on the drilling machine table is by means of T – bolt and clamp.

of T – bolts usually

ranges from 15 to 20 mm.

A drilling machine is a tool used for drilling holes in various materials, such as metal, ceramic wood, or plastic. It can be either portable or stationary. A drilling machine is very versatile and can be used to make a variety of hole types and geometries as listed below:

- Drilling: The most common use of a drilling machine is making either blind or through holes in a workpiece.

- Reaming: Used to finish an already-drilled hole, improving both its dimensional accuracy and its surface finish.

- Countersinking: After a hole is drilled it may be necessary to create a countersink in the workpiece. A countersunk hole has a conical cutout to accommodate the head of a fastener that must be flush with or lower than the surface of a finished part.

- Tapping: Once a hole has been drilled, it may need to be threaded to accept a threaded fastener like a screw or bolt. A tap can be attached to the machine and used to cut internal threads.

- Boring: A drilling machine can be used to increase the diameter of an existing hole through the process of boring.

- Counterboring: A counterboring tool is used to create a shallow, enlarged cylindrical cutout so that a fastener's head will fit flush with or below the work surface.

Among the drilling machine's many benefits are the following:

- High speed: Its main advantage is the drill machine's capacity to quickly drill holes into the workpiece and do other drilling activities at a fair rate of speed.

- Great Output: It has a great output potential. The machine's speed increased throughout time, and the output skyrocketed after the introduction of automatic and particularly radial drilling machines.

- Simple to use: The situation's simplicity consistently maintains a high level of operator productivity.

- Extreme adaptability: Modern drilling machines are extremely versatile due to their numerous spindles, autonomous features, and capacity to drill holes at any angle.

- Longer lifespan and lower maintenance costs:Machines have a very long lifespan and require very little maintenance. They require less upkeep and can be used for extended periods of time.

Disadvantages of Drilling

- Can cause environmental damage – Drilling can lead to harm to the environment, like destruction of landscapes and soil contamination.

- Risk of oil spills – There’s always a hazard of oil spills during drilling, which can pollute water bodies and harm marine life.

- Depletes natural resources – Drilling can exhaust our natural resources, as it involves extracting non-renewable resources like oil and gas.

- Can lead to noise pollution – Noise pollution is another downside of drilling, as the process is loud and can disrupt the peace in nearby areas.

- May harm wildlife habitats – Wildlife habitats may suffer due to drilling activities, as they can disrupt the natural living conditions of various species.

Choosing a drill’s composition will vary depending on its use. Generally, drill bit materials are available in three categories.

High-speed Steel (HSS)

HSS drills are a good choice for drilling soft steels and plastic. They are economical and adaptable for many drilling applications.

High-speed Cobalt (HSCO)

With the addition of 5-8% of cobalt, HCSCO drills provide improved hardness and wear properties and are suitable for drilling steel, cast steel, titanium and other hard materials.

Carbide

Carbide drills maintain sharpness more than any other drill material and are best for the hardest materials, including ceramics, glass, stainless steel and cast iron. While outperforming all other drill materials, carbide drills are brittle and more expensive.

What are the various drill dimensions?

Drills can be custom made to virtually any size, depending upon the application. However, industry standards have set defined drill sizes that are most commonly produced by drill manufacturers.

Drill lengths are also variable, however, there are defined types:

- Jobber length – The most common type of general-purpose drill made for a wide variety of jobs, combining strength and accuracy.

- Mechanics length – These drills have shorter flutes than jobber lengths, providing more strength and rigidity.

- Screw machine length – These are the shortest of the standard drill bits with more rigidity that reduces deflection.

- Extended length – Designed to drill deep holes, extended length drills incorporate long shafts and flutes.

- Taper length – These drills fall between the jobber and extended length bits in terms of dimension.

Cutting geometries

Optimizing these relationships to the application, production goals and workpiece is essential to efficient, cost-effective drilling.

Components of drill geometry to be considered are:

- Point angle – Located at the head of the drill bit, the point angle determines wandering, ease of centering, heat conduction and chip flow.

- Main cutting edges – Connected by the chisel edge, cutting edges perform the actual drilling process.

- Chisel edge – Located in the middle of the drill tip, the chisel edge length determines drill sharpness.

- Flute profile – Facilitates chip removal and coolant flow.

- Guide lands – Guide the drill as it works through the hole.

Rake angle

A drill’s rake or helix angle is the angle between the drill’s leading edge and its axis. Rake angles are generally available between 18 and 45 degrees with 30 degrees being the typical value. Higher rake angles form tightly rolled chips. Lower rake angles tend to form chips that are more loosely rolled. Rake angles also affect cutting temperature and tool life.

Large rake angles are generally employed when drilling softer materials, while smaller angles are used when drilling hard materials that produce smaller, shorter chips.

DIN 1836 addresses helix angles with three groups:

- Type N – Normal helix for materials with normal hardness such as non-ferrous metals and cast iron. Type N helixes are not suitable for softer materials.

- Type H – Longer drawn helixes for brittle material such as steel, hard plastics and laminates.

- Type W – Tightly spiraled helix that produces long, curling chips in soft plastics and metals.

Cutting edge

A drill’s cutting edges are connected by the chisel edge and are responsible for the actual drilling process. Long cutting edges provide better performance in the drilling process.

References

Testbook

https://testbook.com › drilling-mach...Drilling Machine: Learn its working, operations, tools & parts

Comments

Post a Comment

"Thank you for seeking advice on your career journey! Our team is dedicated to providing personalized guidance on education and success. Please share your specific questions or concerns, and we'll assist you in navigating the path to a fulfilling and successful career."